Choosing wheels

Push effort & ride comfort

Major design factors that affect wheel selection are:

-

Push effort on smooth floors

The amount of force required to push equipment on smooth floors such as vinyl, commercial carpet and smooth concrete.

-

Push effort on rough floors

The amount of force required to push equipment on rough floors such as bitumen or over obstacles like elevator door jams and joins between tiles and carpet.

-

Ride comfort

The user-experience due to the degree of tyre 'suspension' and the amount of vibration (and resulting noise) absorbed by the tyres.

Push effort and ride comfort are affected by:

Wheel diameter

- The larger the wheel, the easier to push and the better the ride comfort (ability to pass over bumps and to minimize vibration).

- Why? The larger the wheel, the smaller obstacles are as a proportion of the diameter, resulting in greater momentum.

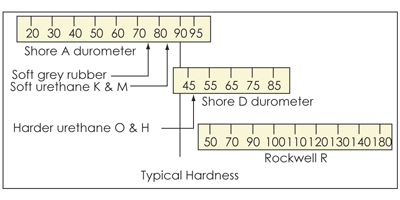

Tyre hardness/resilience

-

Hardness

The harder the tyre, the less out-of-round the tyre will be under load, and the smaller the resulting force required to start the wheel from rest on smooth floors.

-

Resilience (hi-res)

The greater the resilience (bounciness/spring) of the tyre, the lower the sustained push effort required to pass over the multiple obstacles (rough ground).

Why? High resilience materials return energy after compression just like a running shoe (think super balls vs. squash balls - same hardness, different bounciness).

-

Push effort—effects of wheel diameter & tyre hardness/resilience

Summary: Large wheels are easier to push on all floor surfaces. For smooth floors, select harder wheels. For rough floors, select softer wheels.

General factors in wheel selection

In addition to wheel diameter and tyre hardness/resilience the following design factors should be considered:

-

Flat spotting

The compression set (failure to spring-back to original shape) of tyres after long periods under static loads (permanently distorting to out-of-round)

-

Floor marking

The damage to floors (cracks, grooves, scratches, marks, streaks or stains) caused by excessively hard tyres or non-colourstay pigments in tyres.

-

Wear resistance

How quickly abrasion (due to frequent travel on rough surfaces) will cause the tyre to wear away.

-

Particle embedment

The degree to which particles such as swarf or pebbles will get stuck in the tyres (which may then cause damage to floors)

-

Tyre profile

Domed tyres require less force to swivel a wheel (and are generally used in our light to medium duty castor ranges) - note that most Fallshaw light to medium duty castor ranges brake on the sides of the wheels and rely on our domed profiles. Flat profiles spread load and prevent damage to floors at high load ratings (and are used in our heavy and very heavy duty ranges).

-

Bearing type

Some bearings are built to last (hard internal ball tracks or wearing surfaces) with low friction. Others are simpler bearings designed for cost reduction. In general pedestal bearings, precision ball bearings and roller bearings result in lower friction and push effort, with simpler 'plain bearings' being good for corrosion protection and low cost.

Special conditions of use

Specialized applications or conditions of use (such as extreme temperatures or corrosive conditions) will also affect wheel selection - refer to the Specialized Castors pages.

Ease of steering is dramatically affected by the castor arrangement (use and positioning of fixed and swivel castors) - see Designing Tolleys for more information on minimizing push effort through trolley design.

| General factors in wheel selection | |||||

|---|---|---|---|---|---|

| Tyre material | Flat spotting | Floor marking | Wear resistance | Particle embedment | |

| Energy absorbent elastometers | R | OK | Poor | OK | OK |

| S | Good | Excellent | Very Good | Good | |

| T | Good | Excellent | Very Good | Good | |

| J | OK | Excellent | Excellent | Good | |

| A | OK | Very Good | Very Good | Good | |

| O | Good | Good | Good | Good | |

| Hi-res elastometers | B | Very Good | Excellent | Very Good | Very Good |

| Urethane & PVC* | U | Excellent | Very Good | Excellent | Excellent |

| V | Good | Good | Good | Good | |

| Plastics | N | Excellent | OK | Very Good | Very Good |

| H | Excellent | OK | Very Good | Very Good | |

| P | Excellent | OK | Poor | Poor | |

| K | Excellent | OK | OK | Excellent | |

| W | Excellent | OK | OK | Excellent | |

| Sandwich | D | Excellent | OK | Very Good | Very Good |

| Cast Iron | C | Excellent | Poor | Excellent | Excellent |

| Foamed | F | OK | Excellent | OK | OK |

|

For more information on materials for use in specialized applications see Stainless steel / Corrosion-free, High and low temperatures, or Conductive (antistatic) |

|||||