Pneumatic wheels range

Puncture-proof, steel-centred and plastic-centred wheels.

Puncture-proof pneumatic wheels

Premium polyurethane foam-filled tyres for maximum performance and reliability.

Ranging from 50-120 kg capacity.

Pneumatic wheels with steel centres

Pneumatic tyres on wobble-free steel centres for extra strength and performance.

Ranging from 120-360 kg capacity.

Pneumatic wheels with plastic centres

Pneumatic tyres on plastic rims for excellent performance in wet/corrosive environments.

Ranging from 75-200 kg capacity.

Spare parts for pneumatic wheels

Browse range of pneumatic tubes, plastic rims, spacers, bearings, housing and reducing bushes, and pneumatic tyres.

Pneumatic wheels are a great option for carrying loads over uneven surfaces or in environments that commonly require moving over obstacles. They also have the benefit of providing some additional suspension to protect fragile loads on trolleys or additional grip for moving loads outdoors in wet or muddy environments.

Suitable for rugged outdoor terrain, gravel, uneven ground or lawn to smooth pavements and surfaces, Fallshaw pneumatic wheels help to absorb shock, ensuring a smooth and cushioned journey for user comfort and manoeuvrability.

Fallshaw tyres are made from a mix of natural and synthetic rubber in 4 ply (or 6 ply for the 400x8HWY) for excellent durability, abrasion resistance, elasticity and strength.

Please note: Lower quality alternatives on the market have a shiny appearance and a distinctive oil smell, indicating a high proportion of reground tyres (crumbed rubber). This leads to poor strength (particularly around the bead wire which can cause tyres to pop off the rim under load) leading to a short product life.

Typical applications

Whether you are working in warehousing, logistics, construction, industrial sites, or even utilizing heavy-duty machinery, Fallshaw pneumatic wheels are suitable for a wide range of applications including trolleys, hand trucks, outdoor/garden equipment, carts, ride-on mowers, wheelchairs, and beyond.

Hand trucks: Perfect for navigating uneven ground or gravel paths, offering smooth control and reduced vibration when transporting heavy loads.

Wheelbarrows: Deliver superior shock absorption and traction, making them ideal for gardening, construction, and landscaping environments.

Outdoor trolleys: Ensure safe, easy movement of equipment and supplies across rough or sloped terrains, even when fully loaded.

Features across the range

Load capacity between 50-360 kg.

4 ply long life tyres.

One year warranty.

Why Choose Fallshaw Pneumatic Wheels

Ideal for rough, outdoor, or uneven surfaces where air-cushioned movement is needed.

Available in a range of sizes, hubs, and bearings to suit different applications and load capacities.

High-quality rubber tyres provide a stable grip and smooth ride across grass, gravel, and concrete.

Designed for hand trucks, barrows, and industrial carts used in warehouses, workshops, and outdoor facilities.

Australian-made durability, built for long life and consistent performance under variable terrain conditions.

Maximum load capacities

Each wheel can carry the recommended load capacity at walking pace (8 km/h).

If you are intending to tow your load, it is recommended that you do not use wheels with plastic centred rims, or exceed 15 km/h while carrying half the recommended load capacity.

Shop online

Buy pneumatic wheels, castors and spares.

Pneumatic wheels (50-360 kg capacity)

A wide range of puncture-proof, steel-centred and plastic-centred pneumatic wheels.

Shop pneumatic wheels

Pneumatic castors: Y Series

(50-180 kg capacity)

Puncture-proof, steel-centred and plastic-centred pneumatic castors in fixed or swivel plate forks.

Shop pneumatic castors

Spare parts for pneumatic wheels

The range includes pneumatic tubes, plastic rims, spacers and pneumatic tyres.

Shop pneumatic sparesPneumatic tread options

RIB |

Straight lines, grey non-marking rubber. Common for wheelchairs and light duty trolleys that need a softer ride. |

LUG |

General purpose, outside use. Strongly marked cross lines on a fairly flat tread surface. Good for running in a straight line. Use LGG code for grey non-marking rubber. |

LGG |

|

IND |

The normal industrial type tread, a round profile with an even pattern. |

DMD |

Chunky diamond or star shaped pads on a flatter surface. Often used in rougher construction sites. Good for softer grass surfaces but may become clogged with mud. |

STR |

|

|

This knobbly pattern is often preferred for outdoor use, good for gravel or uneven terrain. |

HWY |

Jagged lines on a thick, 6 ply tyre designed to have a higher load rating for industrial work sites. |

GRA |

A wide tread, designed specifically with ride-on mowers and associated equipment in mind. Will traverse virtually any surface they come across. |

Puncture-proof pneumatic wheels fitted to a hand truck/appliance trolley—for extra reliability.

Wobble-free steel centred pneumatic wheel fitted a wheelbarrow—suitable for rugged terrain.

A catering trolley fitted with plastic centred pneumatic castors—suitable for corrosive environments.

Trolley fitted with plastic centred pneumatic wheels—suitable for wet environments.

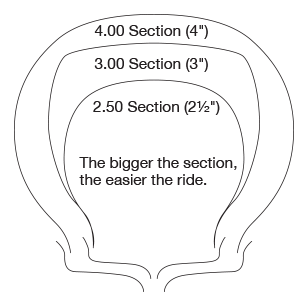

Pneumatics: Nominal wheel size

Our code structure for pneumatics follows an internationally recognised convention that describes:

Tyre width (in inches) x rim diameter (in inches, measured from where the bead wire within the tyre sits on the rim).

So, for example a nominal wheel size of:

250x4 has a tyre width of approx 2.5 inches, on a 4 inch rim.

350x4 has a tyre width of approx 3.5 inches, on a 4 inch rim.

400x8 has a tyre width of approx 4.0 inches, on an 8 inch rim.

Maximum inflation of pneumatics

Warning: Do NOT inflate over recommended tyre inflation pressure (30 psi).

Do NOT allow tyre pressure to drop below 20 psi or wheel may deflate and become very difficult to re-inflate. If you allow the tyre to go flat and you are unable to re-inflate it then you may need to buy an inner tube to be retro fitted to the wheel (available from our Spare parts for pneumatics and general wheels page).

Use of pneumatic wheels other than as recommended can be dangerous.