Trinity EBC

Preventable falls, serious consequences

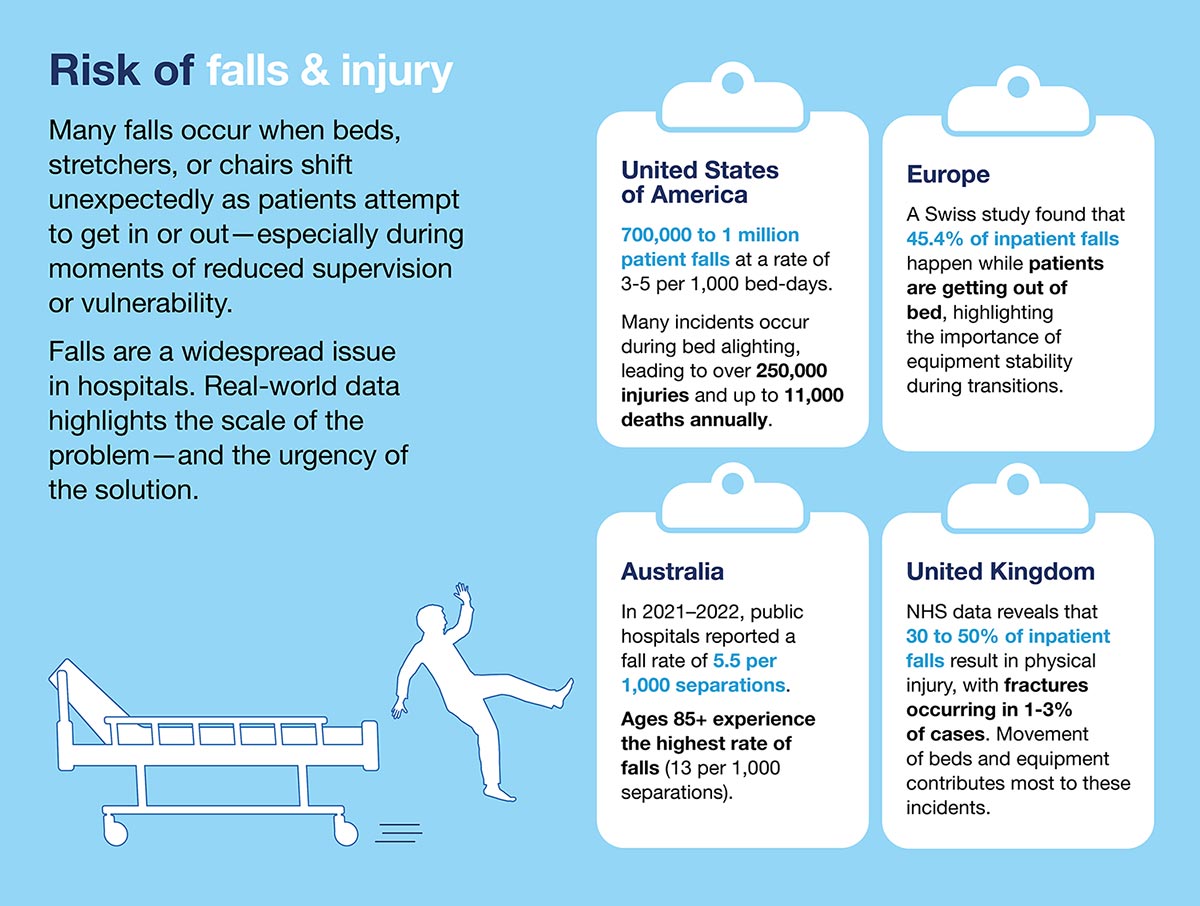

Patient safety is a critical focus for healthcare providers worldwide, and falls remain one of the most prevalent and preventable risks in hospitals. One of the leading causes of patient falls occurs when beds, stretchers, or medical chairs move unexpectedly as patients attempt to alight. These incidents can lead to serious injuries, prolonged hospital stays, and reputational risks for medical facilities.

Integrate EBC into medical equipment

For medical equipment manufacturers, integrating advanced safety features into hospital beds, stretchers, and surgical chairs is key to addressing this challenge. Fallshaw’s Trinity EBC (Electronic Braking Castor) provide an innovative, reliable solution that enhances the stability of medical equipment and supports proactive fall prevention measures.

For manufacturers, these statistics below represent an opportunity to differentiate their products by prioritising safety and stability. By integrating Fallshaw’s Trinity EBC Castors into the initial design, this addresses one of the most common fall risks—unintended movement during patient transfers.

Trinity EBC’s automatic braking system automatically engages brakes to stabilise hospital beds, stretchers, and medical or surgical chairs when not in motion. Made in Australia, this technology ensures that equipment remains stationary, providing a safer environment for patients. The castors have been quality tested and for peace of mind, come with a three-year warranty.

Inpatient falls due to unintended movement of medical equipment remain a significant issue across healthcare systems globally. The above real-world data highlights the scale of the problem and the urgency of the solution.

1. Automatic braking for reliable stability

-

How it works: The castors automatically lock after a set period of inactivity (eg. 60 seconds—can also be programmed for a preferred set time), ensuring equipment remains stationary when not in use.

-

Benefit: This feature eliminates unintended movement during high-risk moments, such as when patients alight from beds or chairs.

Improved patient safety: Automatic braking reduces the risk of falls caused by unintended equipment movement.

2. Centralised, user-friendly controls

For healthcare staff: Foot pedals or integrated control panels enable easy braking, either manually or electronically. Along with the automatic braking ensures the brakes are not forgotten by busy staff.

Intuitive controls helps simplify workflow for healthcare staff, improves manoeuvrability of equipment and helps to reduce the risk of push/pull injuries.-

Compatibility: Seamless integration with control systems like LINAK, DEWERT, and TiMOTION ensures easy adoption into hospital-grade equipment designs.

3. Robust design for medical environments

Durability: Available in sizes of 100, 125, and 150 mm, with IPX6 water resistance and anti-static options to withstand rigorous cleaning protocols.

Customisation: Pedal orientation, braking styles, and colour options (with a minimum order quantity) can be tailored to align with your product’s design specifications/and or branding requirements.

4. Steer from the head or foot end of the bed

With in-built intuitive steering, the castors automatically adjust to accommodate for easy steering from the head or the foot end of the bed, helping to increase efficiency for staff.

5. Full design freedom with electrical cable connectivity

Connecting castors with electrical cables, rather than mechanical linkages, provides full design freedom for healthcare equipment manufacturers. This enables greater flexibility in bed and chair configurations, allowing seamless integration of braking systems without mechanical constraints.

Benefits for manufacturers

- Compliance with regulations: Trinity EBC castors provide automatic braking systems that meet the baseline safety requirements for medical equipment.

- Enhanced marketability: By integrating these castors, your equipment gains a competitive edge, appealing to healthcare providers focused on patient safety, while enhancing functionality and appeal.

- Support for patient-centred care: Stable equipment improves patient confidence, enabling safer movements and faster recovery.

Meeting healthcare standards and guidelines

Trinity EBC castors are designed to align with international safety standards and fall prevention guidelines, such as those outlined by Health Victoria and the Australian Commission on Safety and Quality in Health Care (ACSQHC).

Fallshaw’s Trinity EBC Castors provide a proactive, smart solution for medical equipment manufacturers aiming to meet the highest safety standards.

Find our more

Visit Fallshaw’s product page today to explore how Trinity EBC Castors can be integrated into your designs.